Different Types of Touchscreen Technologies : Capacitive Explained

| Call Us | Email Us | Website |

All touchscreens are not the same.

They achieve the same thing; you place your finger or stylus on the screen and your finger or stylus acts like a cursor or mouse pointer, but there are several different types and they achieve this by using different builds and technologies. There are also pros / cons – advantages and disadvantages to each type.

The four most widely used touchscreen technologies are:

- Capacitive Touchscreens (Projected and Surface)

- SAW (surface acoustic wave)

- Resistive

- Infrared

Resistive and Capacitive touchscreens are most widely used in industrial settings. They are sturdy, reliable and economic.

There are two kinds of Capacitive Touchscreen. Near Field Projected Capacitive and Surface Capacitive.

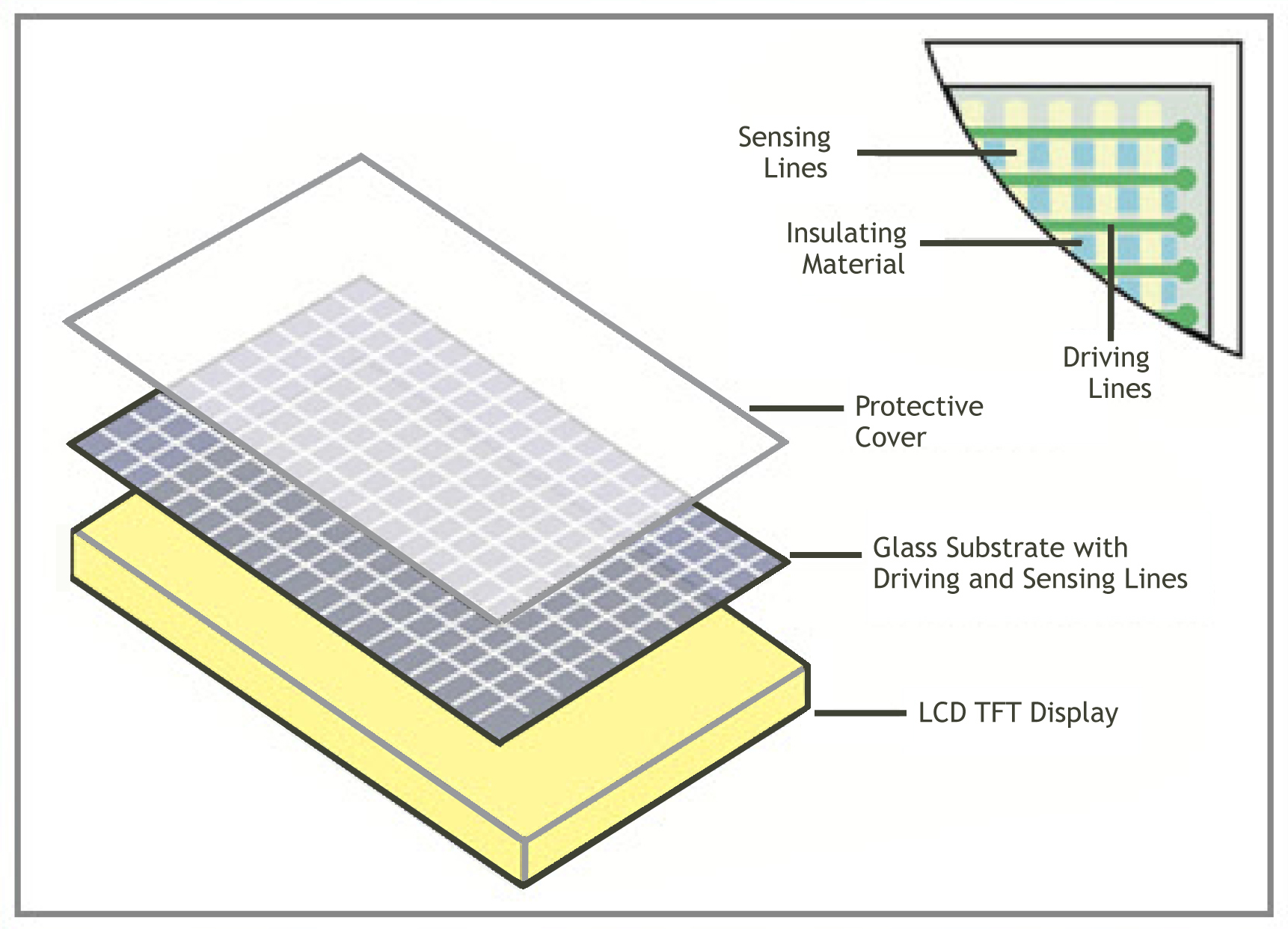

Both Near Field Projected and Surface Capacitive touchscreens are made of a two glass layers. These layers have spaces between them. In between these two layers are tiny capacitors that monitor the electrical field between the two layers of glass. There are two layers of rows of capacitors. One layer of capacitors has rows that run left to right and the other layer has rows that run top to bottom. When a finger is placed on the top glass layer the electro-static field is naturally altered and the difference made is translated into co-ordinates to know where your finger has been placed on the screen.

The electrostatic field on a surface capacitive screen is held or is unable to rise above the surface of the top layer of glass. On a near field projective capacitive screen the electrostatic field slightly projects above the surface of the top layer screen.

capacitive-touchscreen-explained-hired

capacitive-touch-screens-explained

Pros / Advantages of Surface Capacitive Touchscreens and why you may choose one

- These support Multi-touch

- They are very sensitive and can be touched lightly

- The image tends to be brighter and has more clarity than other technologies.

- Resistant to surface dirt and contaminants.

Cons / Disadvantages of Surface Capacitive Touchscreens and why you not may choose one

- They are more expensive to build

- The front layer of glass can be prone to breakages

- Cannot be used by people wearing gloves. (A stylus however can be used)

Pros / Advantages of Near Field Projected Capacitive Touchscreens and why you may choose one.

Largely as above except that because the electrostatic field rises slightly above the top layer of glass, these touchscreens can be used with thin gloves like surgical or cotton gloves.

This is a very simple outline explanation of how projective and surface capacitive touchscreens work. But hopefully goes someway to helping in understanding them.

Phones now are beginning to use In Cell capacative touchscreens and older Capacative Touchscreens can now be referred to as On Cell Capacative Touchscreens. Capacative touchscreens are usually made of several layers because the different parts of the touchscreen are made by different factories / manufacturers , then they are put together by a company that wants to build a particular touchscreen for a particular application. However, the buying power of some of the bigger companies has now enabled them to have screens built specifically for them. This has promoted the construction of In Cell screens where the electrostatic component is within the top layer of glass. This makes for much thinner screens – particularity useful if you are phone manufacturer such as Apple or Samsung etc. We will see thinner phones in the future due to this.

If you wanted to investigate capacitive touchscreens further it is worth researching Mutual Capacitance and Self-Capacitance technology. The following paragraphs are taken from Wikipedia: but is probably more than most people need to know.

Mutual capacitance

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter, or the change in frequency of an RC oscillator. This method produces a stronger signal than mutual capacitance, but it is unable to accurately resolve more than one finger, which results in “ghosting” or misplaced location sensing. However, in 2010 a new method of sensing was patented [42] which allowed some parts of the capacitance sensors to be sensitive to touch while other parts remained insensitive. This enabled Self capacitance to be used for multi-touch without “ghosting” .

To read more on other types of touchscreens use the links below:

SAW Touchscreens Explained

Capacitive Touchscreens Explained

Infra Red Touchscreens Explained

Resistive Touchscreens Explained

Interested in hiring with us? Contact details below: